Sustainability Overview

We believe aluminium embodies the strength required to propel industrial evolution and ignite technological breakthroughs

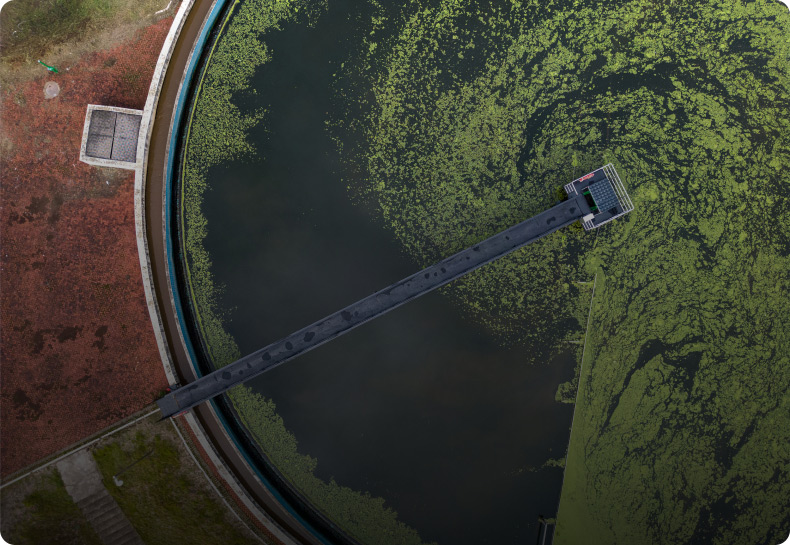

With a forward-looking vision, we have developed a long-term sustainability strategy, seamlessly embedding it into our operations and decision-making. Committed to leveraging our resources, expertise, and global influence, we strive to shape a greener future for aluminium technology.

Current position:Home

Current position:Home